Coatings and acid-resistant brick linings – how to ensure long-term economic benefits

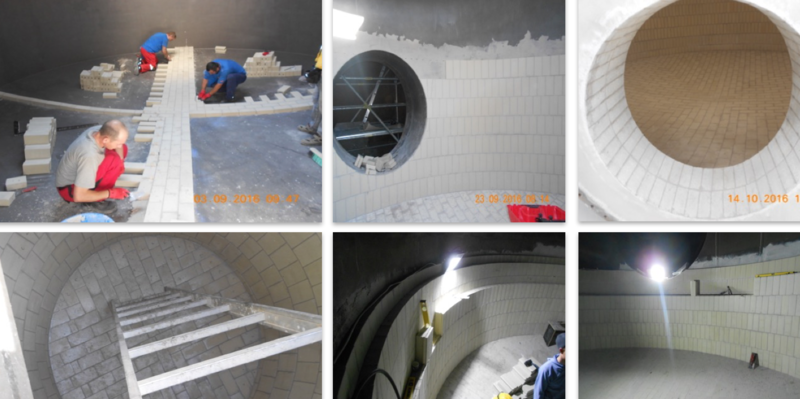

Our services for this project include project management, surface preparation, corrosion protection systems application and continuous quality control.

Do to the exposure of tanks to a wide variety of aggressive acids (phosphoric and sulphuric) and mechanical stress, essential anti-corrosion measures were selected for each tank according to the particular chemical, mechanical and specific environmental conditions.

Our services in this project were divided into 3 factories:

1. Sulphuric acid plant

2. Phosphoric acid plant

3. Leach plant

- Sulphuric acid plant

Surface: 1,625 sqm divided into 9 carbon or stainless steel tanks

Technical solution and services: 3 layers of acid-proof brick lining and rubber membranes (2mm thick rubber membrane). Approx. 30% of acid-proof brick lining was applied in a triple layer and the remaining 70% in a double layer. The acid proof bricks embedded and joined with acid proof mortar had different sizes and thickness (40 mm – 115 mm)

- Phosphoric acid plant

Surface: 14.557 sqm divided in 14 carbon steel tanks, concrete flooring, channels and concrete reaction vessels.

Technical solution and services: inside anticorrosion protection work. The applied systems were composed of:

• rubber membranes (4mm and 5mm thick) (14.557 sqm)

• acid-proof carbon bricks and tiles (with a thickness of 20mm – 120mm), joined with acid proof mortar (12.000 sqm)

• multiple layers of linings (resin layers, reinforced fiberglass layers, epoxy coatings), highly resistant to acids (28.000 sqm)

- Leach plant

Technical solution: We applied acid proof tiles (25 mm thickness) with corresponding acid proof mortars in channels and sumps (1.690 sqm), and we performed epoxy and polyurethane-based lining application (thickness from 2 to 5 mm) on concrete floors and concrete columns (15.013 sqm).

Also in this plant, we applied acidproof rubber membranes in 14 carbon steel tanks (3.900 sqm).

We deliver complete projects or works so you can focus on your core business, ensuring that your plant continues to operate both economically and efficiently. Contact us now and let's talk about your project!