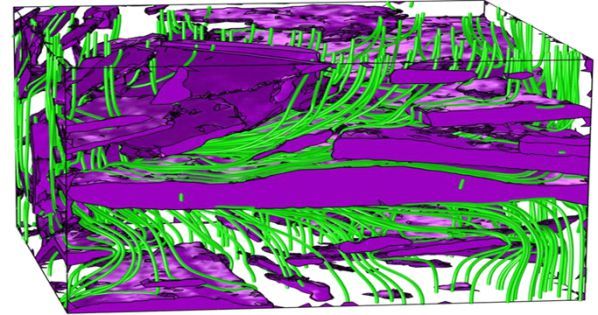

Corrosion paint under X-ray

LCN researchers have revealed detailed 3D image of an important industrial product used to reduce corrosion in the ship hulls. This work, carried out in collaboration with Akzo Nobel, a company in the field of paints and corrosion products, allows the identification of the aluminum powder pigment and filler components. Images were obtained by subjecting a X-ray test to the products.

High resolution images were combined with detailed modeling paint function to produce two key insights. The permeability of the ion, one of the main causes of corrosion was found to be much lower in the direction of the transition to protected area. Also, notice that the structure aluminum plate component has blocked passage of ions . The images look like they are aligned with the surface during paint application.

Images were obtained using a method of viewing 3D X-ray, X-ray called "Ptychography-Tomography", developed at the Swiss Light Source in Villigen, near Zurich. The method is similar to a 3D version used in microscopie- a revolutionary technique in optical microscopy, allowing transparent imaging of biological samples, such as bacteria. Ptychographic-Tomography group was recently used by Pfeiffer in Munich, to view 3D arrangement of bones and is expected to find applications in nanoscience and technology widely.

Professor Ian Robinson, who led the team LCN, made these comments on the outcome: "The work of Bo Chen and colleagues is a good example of the modern scientific method, teamwork between hi-tech industry materials development, facilities characterization and international academic theory and its modeling. Characterization of facilities in Switzerland, an X-ray beam line, in fact, build a particle accelerator, is a specialized and unique result in the world. However, it offers free access to visit researchers for well-justified problems. This approach allows access to other centers such as the Swiss Light Source, to specialize/ develop their equipment to the extreme, which makes it unique in the world. The authors of this paper have applied the method to a material relevant industrial and managed to go further by modeling its service function as barrier layer to reduce corrosion at ship hulls. "

Method and actions were discussed at the workshop on "real and reciprocal space imaging X-ray", which took place on February 11 at the Royal Society in Chicheley Hall, home of the Kavli Royal Society International Centre, Buckinghamshire, UK.

Figure showing the location of the aluminum plate in a 10x10x10 block microns in corrosion product structure for ships. Ions flow lines are shown (green) to mark the slow action of the corrosion.

Source: https://www.london-nano.com/research-and-facilities/highlight/understanding-anti-corrosion-paint, 16 februarie 2015